The following video shows the hot forming of stainless steel curves with molds made in house by our staff. In the past, we used to purchase such parts from external suppliers.

In our sector we often deal with the “make or buy” dilemma, so we have to decide whether to build the single components of a product by ourselves or to buy them from the outside.

But regardless of the decisions that may be different based on the characteristics of the single orders, we believe that “a good metallurgic manufacturer should be able to make any piece of metal” (quote by Luca Tosto).

Certainly the choice of fabricating even the smallest pieces internally is not the most convenient in economic terms, since it is necessary to invest in machinery, spend time, employ people and take on the risk that, in a different way, would fall on the supplier.

But if we look beyond the mere economic choice in the short term, we can understand that the most important investment is the one made in the know-how of the team, which learn how to perform new processes, increasing its expertise: an immaterial resource of inestimable value.

Thanks to our investments in know-how, today we are able to independently construct any manufacturing part.

Related Posts

Thursday March 14th, 2024

(Italiano) StocExpo 2024: Sphero porta a casa un prestigioso riconoscimento

Thursday November 30th, 2023

Walter Tosto Spa supports the Ukrainian Women’s Handball Team in the Women’s World Championship

Thursday September 7th, 2023

Walter Tosto at the round table “Selling Machinery in China” with Sace and Sumec

Wednesday June 14th, 2023

New delivery: Vacuum Column for Distillate Hydrotreating Unit

Monday March 20th, 2023

Walter Tosto SpA among the Top 200 companies in the Abruzzo and Molise regions

Tuesday February 14th, 2023

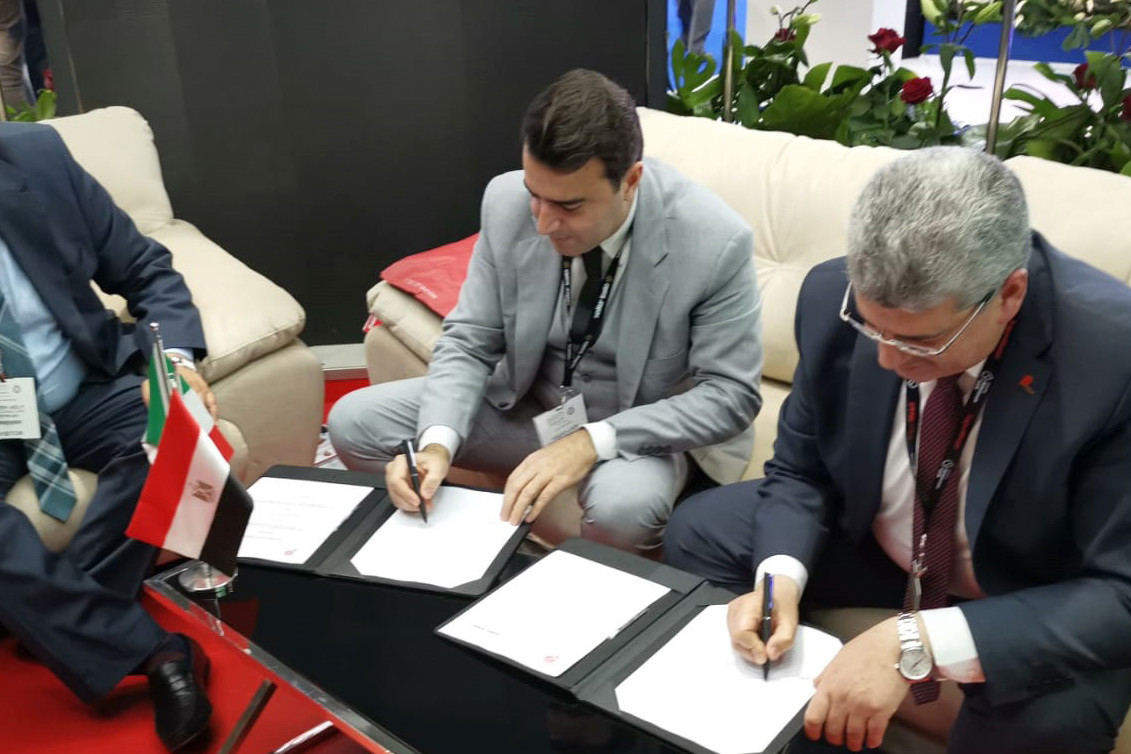

Petrojet and Walter Tosto renew their cooperation agreement for Oil & Gas projects in Egypt

Wednesday February 1st, 2023

Walter Tosto welcomed important delegates for the ITER project

Monday January 30th, 2023

Walter Tosto SpA meets the students of the Technical Institute “T. Acerbo” of Pescara

Wednesday January 11th, 2023

The first shipment of the year is preparing to land in Egypt

Monday November 28th, 2022

Students from the school of Collecorvino to visit Walter Tosto spa

Friday October 14th, 2022

Walter Tosto in Brussels to talk about new technologies in the nuclear field

Wednesday June 15th, 2022

Awarded the first Welding Operators of the “Di Marzio-Michetti” institute of Pescara

Wednesday January 26th, 2022

Important milestone for the international scientific community: Borexino comes to an end

Thursday October 14th, 2021

Centenary of the Professional Institute “Di Marzio – Michetti”

Thursday May 27th, 2021

New training project for students with Walter Tosto’s technicians

Friday April 2nd, 2021

Quality, Walter Tosto obtains the renewal of the ASME certification

Monday January 18th, 2021

Walter Tosto SpA enters the “Patent Box” subsidized taxation regime

Friday December 11th, 2020

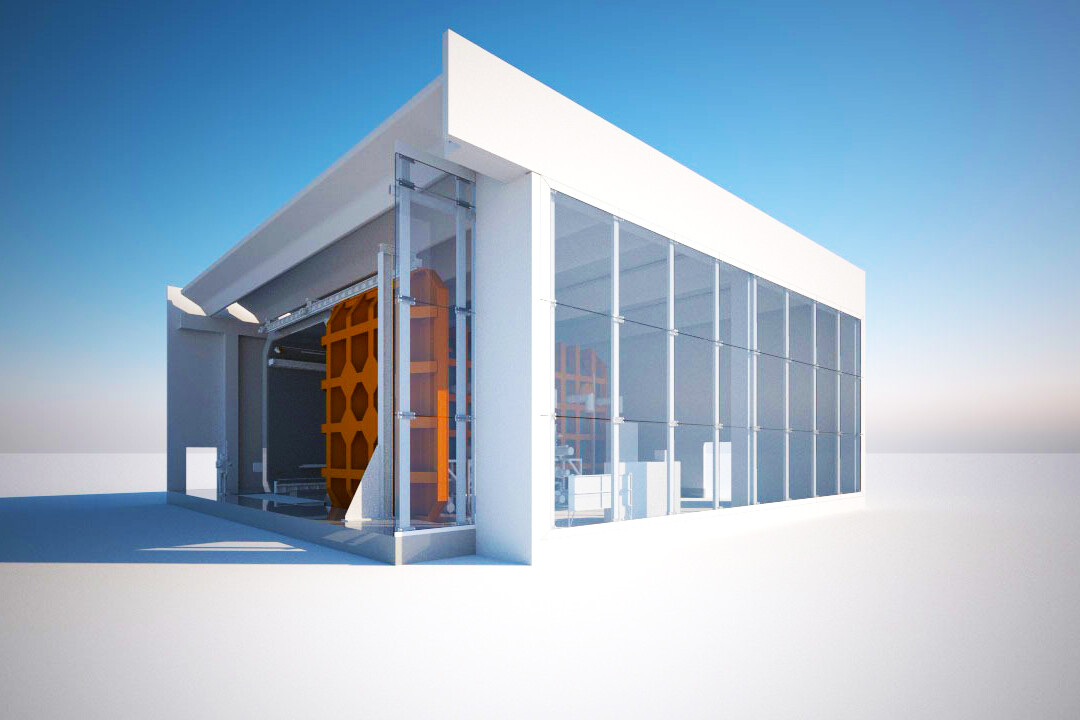

Concentrating solar plants: the Nextower project is taking shape

Wednesday October 28th, 2020

Equipment designed by Walter Tosto to be installed in Illinois

Friday February 14th, 2020

Opportunities in Egypt: The agreement between Walter Tosto and Petrojet has been renewed

Friday December 20th, 2019

Waste Heat Boilers for methanol plant in Saudi Arabia just shipped

Tuesday November 5th, 2019

More than 100 students are attending high-level courses in Walter Tosto SpA

Friday October 18th, 2019

Industry 4.0 course in Walter Tosto: 24 students to start the internship phase

Friday September 13th, 2019

Students of the Master in Fusion Energy visit Walter Tosto SpA

Thursday September 5th, 2019

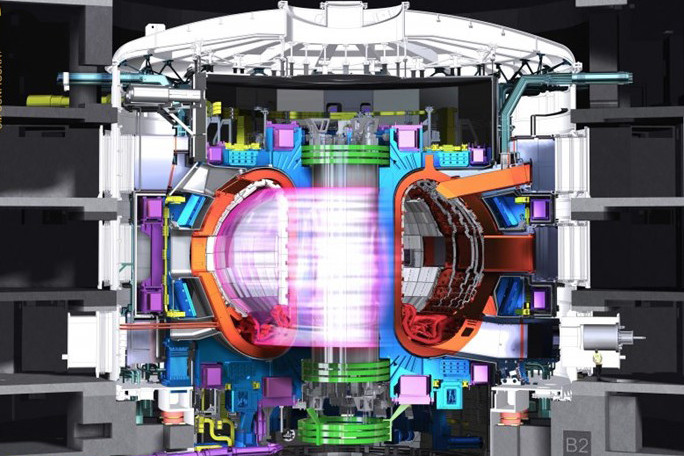

ITER: a crucial step was reached for the Vacuum Vessel’s sectors construction

Friday July 12th, 2019

Intesa Sanpaolo to visit the Tosto Group in its headquarters in Chieti

Tuesday June 25th, 2019

ITER Project: Delegates of the Chinese government to visit Walter Tosto SpA

Monday May 13th, 2019

Tour in Walter Tosto for 110 technical institute students of Pescara

Wednesday April 17th, 2019

Nuclear: Research and Industry for Young Generation Conference

Thursday April 4th, 2019

Fluor and Exxon Mobil grant a prestigious award to Walter Tosto SpA

Monday February 18th, 2019

Walter Tosto and Petrojet to sign an important agreement in Egypt

Wednesday December 19th, 2018

Walter Tosto to welcome 25 future industry 4.0 technicians

Wednesday December 12th, 2018

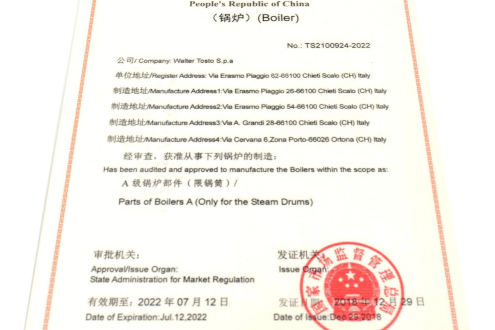

Quality: positive results for the renewal audit of the SELO certification

Monday December 3rd, 2018

Tosto Group and UBI Banca together for Foreign Markets opportunities

Friday November 23rd, 2018

At Palazzo Alteri with Banco BPM for the presentation of the new book of Carlo Verdone

Wednesday November 14th, 2018

The new training program for future industry 4.0 technicians was presented today

Monday September 17th, 2018

September 13th and 14th 2018: Ninth edition of the Dillinger Pressure Vessel Colloquim

Thursday September 13th, 2018

Banco BPM and Gruppo Tosto: a collaboration coming from the past and looking to the future

Monday March 5th, 2018

The students of the Industrial Institute at Heavy Industry lesson

Thursday November 9th, 2017

ASME reconfirms Walter Tosto with the certification for nuclear components

Friday September 8th, 2017

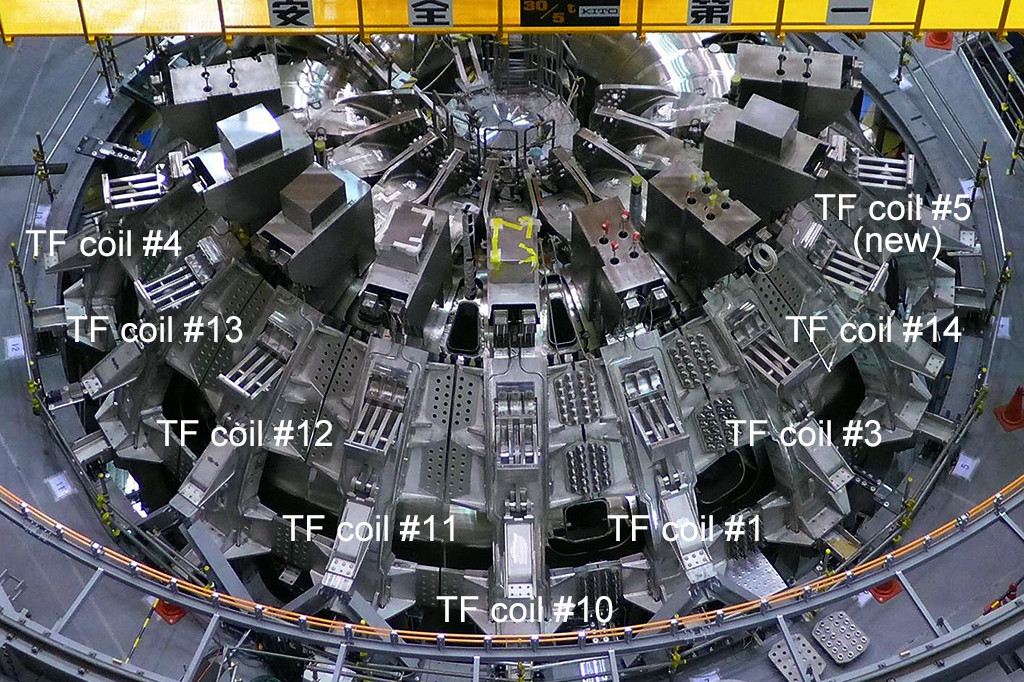

The last TF coil for the JT-60 SA project has been delivered

Thursday March 23rd, 2017

Walter Tosto joined the Energy, Construction and Dwelling hub

Monday February 6th, 2017

Meeting with the Boards of the AMW consortium and Fusion for Energy

Thursday February 2nd, 2017

Speech of Prof. Testa to the Commission for Productive Activities

Tuesday January 24th, 2017

Walter Tosto recognized sustainable company of advanced level

Monday December 19th, 2016

WT’s employees performed in a talent show for the Christmas Dinner

Wednesday December 14th, 2016

A new milestone in nuclear fusion: Wendelstein 7-X works!

Tuesday November 22nd, 2016

The Undersecretary Claudio De Vincenti visited Walter Tosto SpA

Wednesday October 19th, 2016

October 25 to 28, 2016 : Food and Pharma will participate to Cibus Tec

Wednesday October 5th, 2016

Walter Tosto was invited as a judge at the “Brodetto” Festival

Wednesday October 5th, 2016

New York celebrates the arrival of the first pieces of the panoramic wheel

Friday September 9th, 2016

A special cargo for Walter Tosto: New York Wheel is the mission

Friday September 2nd, 2016

BNL Commercial Corporate Management visiting Walter Tosto SpA

Friday September 2nd, 2016

(Italiano) Opportunità di lavoro per un manutentore meccanico

Monday July 4th, 2016

Master’s student in fusion energy attend a lesson at Walter Tosto

Wednesday June 22nd, 2016

(Italiano) La Walter Tosto seleziona un addetto/a alla contabilità clienti

Friday November 20th, 2015

Entrepreneurs and Local Administrators meet up to talk about Energy

Thursday October 22nd, 2015

Rome, October 29-30. Walter Tosto participates to Oil&NonOil 2015

Tuesday September 22nd, 2015

Convention: the centrality of the project and the engineer’s role

Wednesday August 26th, 2015

Walter Tosto is the main sponsor of the Chieti football team

Thursday July 9th, 2015

Millionaires agreements between Italy and Kazakhstan at Expo 2015

Thursday May 21st, 2015

Even Luigi Febo chooses Walter Tosto for his political campaign

Wednesday May 6th, 2015

The mayor of Chieti starts his political campaing from WT’s workshops

Thursday March 19th, 2015

Power Division: firsts casings for the JT-60SA project are ready

Monday February 16th, 2015

Congratulations to the new F4E’s Director, Pietro Barabaschi

Thursday December 18th, 2014

University of L’Aquila: Walter Tosto SpA at Career Day 2014

Thursday November 6th, 2014

Sochi Winter Games: Walter Tosto SpA obtains a millionaire order

Tuesday November 4th, 2014

Walter Tosto SpA participates to the Economic Forum “Both Worlds 2014”

Monday October 27th, 2014

Walter Tosto Spa welcomes Fusion 4 Energy for the ITER project

Wednesday October 8th, 2014

Food & Pharma, WT SpA’s division, participates to CibusTec2014

Wednesday October 1st, 2014

Italy at CERN: an excellent showcase for the italian industry

Wednesday September 10th, 2014

New confirmations and renewed trust: when team play is the key

Tuesday September 9th, 2014

Master in Walter Tosto SpA: an extraordinary opportunity for young people

Thursday July 31st, 2014

University of Bucharest awards the excellence of Walter Tosto SpA

Thursday July 31st, 2014

Luca Tosto will talk about Fecne to the Forum “Opportunities in Romania”

Thursday July 31st, 2014

The Brazilian Petrobras reconfirms his trust in Walter Tosto SpA

Wednesday July 30th, 2014

The first manufacts Walter Tosto Rus leave the Adriatic coast

Wednesday July 30th, 2014

Walter Tosto contributes to the construction of the Wheatstone mega-project

Friday July 25th, 2014

Walter Tosto SpA welcomes students of Chieti, Pescara and Bucharest

Monday July 21st, 2014

Aipe, the Italian Association of Pressure Equipment has been launched

Thursday July 17th, 2014

July 30-31, 2014, Houston. Walter Tosto SpA will attend the GTL Technology Forum

Tuesday July 8th, 2014

Walter Tosto contributes to the construction of the Wheatstone mega-project

Siamo all’Expocentre di Mosca per partecipare all’evento Neftegaz 2018 insieme alle altre aziende del Gruppo

Italiano

Italiano