The company carries out its activities in nine workshops, seven of them are located in Italy, six in Chieti and one in the Port of Ortona, on the Adriatic sea, allowing the direct shipment by sea of the items with no size and weight limitations.

Two of the workshops are located in Romania (Walter Tosto WTB), one in Bucharest and one in Oltenita on the Danube river where a private river port allows to carry out all the logistic operations for river/sea shipping.

Number of workshops: 6 – Covered Area : 91.000 sqm – Uncovered Area: 340.000 sqm

| Workshop | Address | Offices Area (sqm) | Covered Area (sqm) | Uncovered Area (sqm) | Total Area (sqm) |

| WT1 | Via Erasmo Piaggio n.72 | 100 | 3.680 | 4.400 | 8.180 |

| WT2 | Via Erasmo Piaggio n.62 | 1.450 | 8.716 | 8.716 | 31.960 |

| WT3 | Via A. Grandi | 360 | 4.925 | 4.925 | 44.925 |

| WT4 | Via Erasmo Piaggio n.26 | 2.054 | 9.400 | 9.400 | 31.640 |

| WT5 | Via Erasmo Piaggio n.54 | 250 | 25.540 | 25.540 | 88.545 |

| WT7 | Via A. Grandi | 9.102 | 9.102 | 59.772 |

Walter Tosto owns one sea-front workshop (WT6) directly located in the Ortona Port, on the Adriatic Sea, where 3 quays are present with the following features:

1. RIVA: Height: 1.60 mt, Water Depth: 6.00 mt

2. RIVA NUOVA : Height: 2.00 mt, Water Depth: 6.00 mt

3. NORD NUOVA : Height: 2.00 mt, Water Depth: 7.00 mt

To date, this workshop has allowed us to complete and ship, in one piece, items with noteworthy dimensions. From here, in fact, it is possible to ship items with up to 15 mt of diameter, up to 100 mt lengths and over 1.500 tons of weight.

Furthermore, with over 9.000 sqm of covered facilities, Ortona’s three covered spans are each equipped with double overhead cranage with unique lifting capacities. The significant dimensions of our furnace for Post Weld Heat Treatment (29mt x 11mt x 10mt) allows us to minimize the quantity of localized PWHTs, while its “Cooperheat” combustion system assures a more rapid and uniform heating while allowing an accurate control of the overall temperature within the furnace (maximum deviation +5%).

Walter Tosto WTB, our subsidiary located in Bucharest, operates mainly in the nuclear components sector. With its covered 25.500 sqm, the workshop is specialized in the manufacturing of critical items with a consolidated history in pressure vessels for the nuclear sector. The company (previously known as Fecne) was acquired by Walter Tosto in 2012, which identified in the factory a high potential opportunity for the continuation of its growth in the nuclear market. The workshop infrastructure is now completely renewed with energy efficient improvements, new machinery equipment and modern facilities for employees.

We own a facility with a covered area of 7.700 sqm and an uncovered area of 72.000 sqm in the Port of Oltenița, at about 60 km from our main workshop in Bucharest. All logistics are carried out by self-propelled trailers, mobile cranes and our own access ramps to the river for roll-on and roll-off operations.

Walter Tosto aims to place itself among the world’s élite manufacturers of critical items. To achieve this, we are equipped with a wide machine park and innovative technologies, which allow us to internally carry out all the critical activities. As a result, the company is able to manufacture and transport products without weight and size limits.

Dino 9000

Dino 9000 is a rolling machine entirely engineered and assembled in-house by our staff and features the following characteristics:

Press capacity for Vanadio: 9000 Tons

Thk: 300 x 3600 Length, min

Dia: 2.200

Rolling Thk: over 300 mm Cold (subject to material type and width)

3 rolls with plate rolling machine with geometric adjustment configuration

Waldrich Coburg

With a length of over 35 meters and a height of over 10 meters, the Waldrich PowerTech Milling Machine represents a unique item equipment, the largest portal milling machine in the world for its accuracy.

Nr. of Axis: 5

Net size: 10m x 10m x 35 m

Correa Versa

Correa Versa is a Gantry Milling Machine. It has 5 axes able to machine pieces up to 10,5 m in length, 1,65 m in height and 6,8 m wide with very tight tolerances.

Furnaces

Walter Tosto owns 5 Fournaces for Heat Treatment operations of different size, temperature and thermocouples. The biggest one is located in the Ortona’s workshop and has the following dimensions: 11 meters length, 10 meters height and 28 meters depth.

Furthermore, Walter Tosto SpA owns a hot air ventilated furnace with no limits dimensions.

The welding process is the core of our manufacturing activities.

Our Welding Department is able to employ the following welding processes:

|

Welding Process employed |

Manual |

Automatic |

|

Shielded Metal-Arc welding – SMAW |

X |

|

|

Submerged-Arc Welding – SAW |

X |

|

|

Subm.-Arc Weld. with strips – SAW STRIP |

|

X |

|

SAW Double Wire – SAW Tandem |

|

X |

|

Gas Metal-Arc Welding – GMAW |

X |

X |

|

Gas Tungsten-Arc Welding – GTAW |

X |

X |

|

Flux-Cord Arc Welding – FCAW |

X |

X |

|

Electro Slag Welding – ESW |

|

X |

|

Plasma-Arc Welding – PAW |

|

X |

Robotic welding beam

Our robotic welding system is able to coordinate 8 axes simultaneously (six of which are anthropomorphic + 2 axes, vertical and horizontal respectively) and allows to coordinate repeatability of 0.1 mm. The robot’s load-bearing structure has been designed to ensure minimal bending at maximum extension. The entire system constitutes a very large work area that allows to arrange pieces to be welded in a circular way around the beam.

Dimensions

- Height: 10900mm.

- Maximum width (with open stabilizer): 3920mm.

- Maximum length (with X1 / X2 axis extended): 14500mm.

- Maximum range at the tip (with X1 / X2 axis extended): 1000Kg.

- Y axis stroke: 7350mm.

- X axis total stroke “X1 + X2”: 8600mm.

- Y axis rotation: 0-330 °.

Welding equipment installed

The system is currently equipped with a TIG Narrow-Gap welding torch with arc oscillation driven by magnetic field and double-wire filler material.

Internal Bore Welding

This particular welding is performed using a gun inserted in the tubesheet hole with a rotating head. With special tools is possible to re-build the seat when is necessary to cut the tube already welded.

Electro Beam Welding with PRO-BEAM partnership

For the construction of the Vacuum Vessel, Walter Tosto, with the cooperation of PRO-BEAM, has developed and qualified procedures for the execution of EB welding. EB welding, thanks to the law heat input during the activities, allows a better control of the related deformation.

The full knowledge and the familiarity with all the existing design codes such as ASME, BS 5500, CODAP, Stoomwelzen, AD Merkblatt and GOST allow us to develop the best design from the mechanical point of view. Furthermore, the in-house presence of FEM experts, together with the several ANSYS licenses, make the Finite Element Analysis a powerful instrument in our hands, for the design of critical parts of the equipment.

In addition to the mechanical design, Walter Tosto has strong skills in the development of the thermal and fluid-dynamic design of Heat Exchangers for the Oil & Gas and Power industries, starting from Process Data Sheets, ensuring all the required guarantees to our customers.

Our design activities include:

• 3D simulations

• Stress analysis by finite elements methods

• Fracture mechanics analysis

• Static analysis in steady and unsteady conditions

• Fatigue analysis

• Creep fatigue damage evaluation

• Thermo-hydraulic design of heat transfer systems

Design codes and standards

| ASME I | ASME III Ed.2007 Add. 2009 | ASME VIII Div.1 latest edition |

| ASME VIII Div.2 latest edition | ASME VIII Div.3 latest edition | PD 5500 |

| AD Merkblatt 2000 | VSR | STOOMWEZEN |

| SELO | API 579 – 1 ASME FFS-1 | API 620/650/660 |

| CODAP 2000 CODRES | HEI | GOST |

| IBR | TEMA | EN 13445 |

| IBC 2006 | UBC 97 | ABSA |

| ASCE / SEI 7-05 | BS 7910-2005 | EJMA 9TH Ed. |

| EN 1405 | ASME B 16.5 | ASME B 16.47 |

| API STD 6A | API 934 – 941 | NACE MR 0175/ ISO 15156-3 |

| RCC-M e RCC-MR – nuclear sector | EUR (European Utility Requirements) – nuclear sector | ABSA |

Main Design Softwares

| Finglow: PD5500 pressure vessels calculation software |

| Solid Edge: 3D drawing calculation software |

| Pro ENGINEER: parametric 3D drawing program |

| CATIA V5 R20: 3D drawing program |

| ANSYS: finite element analysis and CFD analysis |

| ASPEN Shell & Tube Exchanger Design Rating Software |

| Aspen Exchanger Mechanical Design Software |

| Sant’Ambrogio: mechanical calculation software for VSR, ASME VIII |

| Div. 1 + EJMA expansion joints module |

| ASME VIII Div. 2, AD 2000 Merkblatt + expansion joints module, WRC 107/297 |

| AUTO CAD AUTODESK: 2D drawing program |

Metrology softwares

| New River Kinematics: Spatial Analyzer |

| Innovmetric: Polyworks |

| Hexagon: Emscon, Tracker Pilot, RDS |

| Aberlink: 3D MKIII |

We strongly believe in the importance of R&D and innovation as contributions for the development of a new sustainable and inclusive social economy.

In compliance with the definitions adopted by the Frascati Manual and the Oslo Manual defined by the OECD, the company carries out applied research, experimental development and innovation activities, adding value to itself and to its stakeholders.

Most of the R&D projects are linked to production needs and purposes and are based on technical engineering activities for the development of tests, prototypes and pilot plants.

The interactions of the R&D department with other company functions reduce risks, enhance company resources and knowledge by generating a favorable to change “cultural environment”.

Our research and development activities in figures

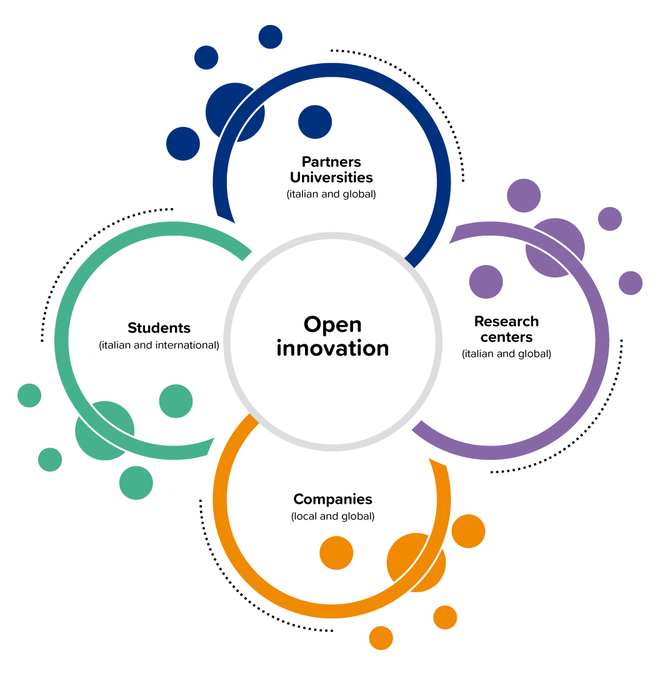

Open Innovation

Innovation is not just technology. It reflects a cultural change that consists of a new way of relating to the world.

For our innovative projects we make use of the support of a network of highly specialized partners – including 21 Universities and 16 Research Centers – to add value to our know-how.

R&D Projects Areas

Over the last three years, the company has developed several projects in the following areas: evolutionary and adaptive production systems, renewable energy, energy efficiency, CO2 emission reduction, green hydrogen, circular economy, advanced materials, processing, innovative products and machinery, digitalisation.

Italiano

Italiano